Breaking Through SMT Technology Amid Industry Transformation: Triple Innovation to Empower Electronic Manufacturing Upgrades

Time:2025-11-07

Views:17

According to the latest report from SEMI, global semiconductor equipment shipments surged by 24% year-on-year in the second quarter of 2025, reaching $33.07 billion. The recovery of the electronic manufacturing industry is driving accelerated iteration in SMT technology, with breakthroughs in miniaturization processes, intelligent production line upgrades, and green manufacturing transformation becoming the core growth drivers for the sector.

From March 25 to 27, 2026, the Munich Shanghai Electronic Production Equipment Exhibition (Productronica China) will kick off at the Shanghai New International Expo Center (Halls E1–E5, W1–W3). With nearly 100,000 square meters of exhibition space and over 1,000 participating companies, this event will showcase the technological transformation of SMT.

Micro scale Attack: Entering the "Micro level Mounting Era"

With the deepening of the trend of "lightweight, thin, and small" in consumer electronics and the improvement of the integration of automotive electronic components, the unit density of 01005 components on PCB boards has increased by more than 300% compared to five years ago. Its mounting accuracy requirements have been tightened from the traditional ± 0.05mm level to ± 0.025mm level. At the same time, it also needs to deal with technical challenges such as component moisture absorption and difficulty in post mounting detection. This has prompted leading enterprises to launch targeted solutions from both equipment hardware upgrades and software algorithm optimization.

FUJI‘s NXTR A model achieves automatic replacement and replenishment of feeders through intelligent loading vehicles, supporting multi variety mixed production and continuous feeding, significantly reducing line changing time and manual intervention. Its modular design allows for free combination of 1R/2R modules, equipped with lightweight working heads for quick replacement, and can expand production capacity as needed. The mounting accuracy reaches ± 15 μ m (high-precision mode), equipped with dynamic height compensation function to cope with circuit board warping, integrated MPI mounting confirmation, IPS component detection, 3D coplanarity detection and other multiple quality guarantees. The new working head supports a wide range of components from 0201 to 200 × 150mm, coupled with dual robotic arms at a top mounting speed of 120000 cph. The single track can handle large circuit boards of 750 × 610mm.

Europlacer‘s iineo series of new generation surface mount machines ii-N1 and ii-N2. The new model is designed to meet the needs of small and medium-sized production of multiple varieties and product trial and installation. It has multiple functions and comprehensive intelligence. The single machine has up to 264 8mm feeder stations, and there is also a tray feeding area inside the body that can accommodate up to 10 standard JEDEC trays, providing comprehensive solutions for short and loose materials; The maximum size for mounting circuit boards is 1610mmx600mmx10mm, and the range for mounting components is from 03015 (metric) to 99mmx99mmx34mm; The mounting speed can reach up to 30000CPH. The new model has also upgraded its RC control software, adopting an intelligent PCB conveyor system and an ultra-high resolution visual system, perfectly integrating precision, efficiency, and unparalleled flexibility, providing customers with better choices.

The new generation MYPro A40 mounting solution launched by Mycronic is equipped with a brand new MX7 high-speed mounting head technology. The new platform has increased the maximum mounting speed by 48% and the size of the mounting components has been expanded by 6 times. MYPro A40DX, With its outstanding flexibility, it achieves unprecedented production capacity for high mixed load users! The rated maximum speed of this model reaches 59000 CPH (mounting capacity per hour), which is improved by the new MX7 mounting head, which integrates 7 independent mounting nozzles controlled by 14 independent Z-axis and θ axis motors. The advanced and professional motion control system updates at a rate of 80000 times per second, optimizing up to 224 interchangeable material stations and each patch action in the 640x510 mm circuit board working area, not only retaining the original flexibility, but also taking accuracy and speed to the next level.

The YAMAHA high-end and efficient module placement machine YRM20, represented by Guangdai, has an ultra high speed turret RM placement head and an in-line FM placement head for opposite sex components. The ultimate improvement of the "single placement head solution" achieves the fastest placement speed of 115000CPH in the 2 beam and 2 placement head levels. In addition, the YRM20 standard is equipped with various functions that can maintain high-quality mounting. The eATS30 non-stop tray feeding device enables efficient tray component replenishment and non-stop production, making it a versatile surface mount machine with outstanding productivity and versatility.

Green Transformation: Efficiency Revolution of Lead free Process

With the continuous upgrading of environmental regulations such as EU RoHS 3.0 and China‘s "Management Measures for Pollution Control of Electronic Information Products", coupled with the growing demand for "carbon neutral manufacturing" from downstream customers, the penetration rate of lead-free processes in the consumer electronics field has reached 98% by 2025. However, the new low-temperature solder (liquid phase line temperature reduced to 170 ℃) not only reduces the thermal stress of PCBs, but also puts higher requirements on the temperature control accuracy and vacuum environment control of welding equipment. In addition, the industry is also facing the pressure of rising energy consumption costs, which is driving equipment manufacturers to continue to break through in energy-saving technology and environmental design.

Several heavyweight welding systems under Rehm, among which VisionXP+Vac vacuum reflow soldering system achieves high efficiency and energy saving by equipping EC motors, reducing operating costs and emissions. Its vacuum module can directly remove pores, air bubbles and voids in the molten state of solder without the need for external vacuum system assistance. The Condenso XS Smart gas-phase welding system adopts a new vertical opening and closing furnace design, optimizes airtightness to achieve higher process repeatability accuracy, supports manual or automatic loading system configuration, has multiple cooling options and patented vacuum injection principle, and can flexibly adapt to local automated production environments.

HELLER‘s newly launched Short Cycle Vacuum Reflow Oven (SCVR) high-speed vacuum furnace in 2025 empowers the high-end electronic manufacturing field with breakthrough technology, providing efficient and reliable solutions for high-precision welding scenarios such as 5G communication, automotive electronics, aerospace, etc. This device deeply integrates vacuum environment control and high-speed reflow technology, significantly improving welding quality while shortening production cycles, becoming a benchmark for innovation in the field of precision welding.

Intelligent reconstruction: digital twins run through the entire production process

Against the backdrop of multi variety and small batch production becoming the mainstream in the industry, and customer delivery cycles continuously shortening, using IIoT technology to achieve intelligent upgrading of SMT production lines has become the core path for enterprises to reduce costs and increase efficiency. Intelligent production lines can not only increase equipment utilization (OEE) from around 65% of traditional production lines to 92% through device interconnection and data analysis, but also rely on real-time sensor monitoring and AI algorithms to achieve predictive maintenance, reduce unplanned downtime by 70%, and meet the compliance requirements of automotive electronics and medical electronics for full traceability of production processes.

ITW EAE has launched an innovative oxygen content closed-loop control system for the reflow oven field, specifically designed for CATHOX ™ The design of the nitrogen furnace ensures precise control of the oxygen content set point within the range of 200PPM to 2000PPM. The system can accurately maintain a target of+/-100PPM in the low oxygen content range of 200PPM to 500PPM, while in the high oxygen content range of 500PPM to 2000PPM, it can remain within 20% of the target set value. In production mode, the closed-loop control system ensures the stability of PCB quality; In standby mode, it effectively reduces nitrogen consumption and automatically returns to the preset PPM value when the machine is put back into production. CATHOX with patented technology ™ The hot oxygen catalytic system significantly reduces maintenance requirements while maintaining a clean production environment. During the reflow soldering process, the system can efficiently remove volatile compounds from the furnace, convert organic gases into hydrocarbons, and capture them through a filter. Centurion ™ The design concept is also reflected in its convenient maintainability, where users can easily complete operations without the need for any tools during maintenance.

The new generation SMT intelligent equipment GenS series launched by ASYS Group upgrades traditional systems into learnable intelligent solutions. Modular architecture can dynamically adapt to your needs, intelligent energy management, and reduce the use of pneumatic components, which helps optimize carbon footprint and energy consumption. The combination of multi touch interface and multi-color technology ensures an excellent user experience; Dynamic driving can shorten the cycle time to less than 10 seconds. Make your production more intelligent and sustainable! Covering application areas such as handling, laser marking, printing, testing/burning, board splitting, and SMD reel storage. Stronger performance, AI capabilities that support transformation and upgrading, and sustainable design that benefits both ecology and economy.

The perfect combination of Borui‘s advanced fully automatic surface mount machine XJ10 and SMT intelligent platform is committed to providing customers with high stability, high precision, high efficiency, and cost-effective products and whole line solutions. The XJ10 integrates an integrated casting structure, fully linear motor drive, fully linear closed-loop control system, high-speed and lightweight HM mounting head, and is equipped with a dual recognition system of a flying camera and a multifunctional camera to achieve precise mounting of 0201. It can be applied to various electronic mounting fields to meet the needs of different customers.

The online laser welding machine independently developed by Ruitian has the characteristics of energy conservation and environmental protection, small welding points, and high adaptability. At the same time, its high efficiency, wide range of weldable materials, uniform heating, small heat affected zone, and fast heating speed have been widely praised by customers in the market. It is also a product carrier for Ruitian Zhineng to promote the upgrading of intelligent manufacturing industry and help China‘s manufacturing leap towards "smart" manufacturing in China.

Exhibition Highlights: Dual Drive of Technology Implementation and Business Integration

With the breakthrough of local SMT enterprises in the localization and replacement of core equipment, as well as the increasing demand for "whole line solutions" in downstream industries, this year‘s Munich Shanghai Electronic Production Equipment Exhibition will focus on showcasing the innovative achievements of local enterprises in printing, mounting, testing, welding and other aspects. At the same time, customized technology docking services will be provided based on the needs of sub sectors such as automotive electronics, new energy, and medical electronics.

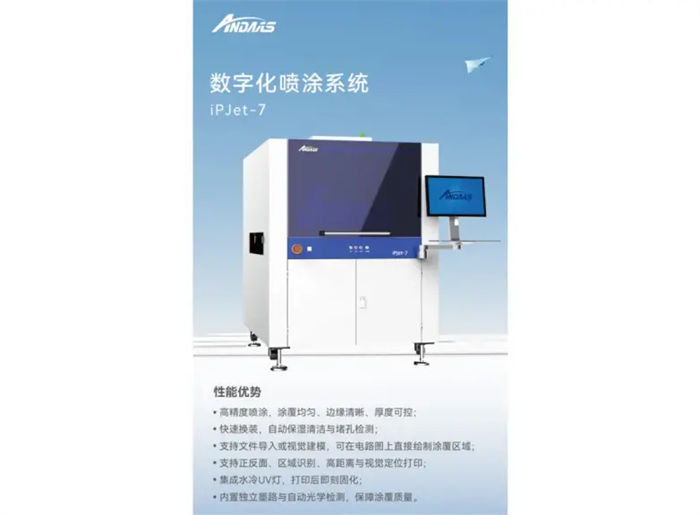

The digital spraying solution launched by Anda Intelligent combines 3D printing, machine vision, and digital modeling technologies to easily handle complex 3D workpiece surfaces, achieve uniform coating, and save paint, making it a model for future intelligent production. Innovatively using spray adhesive 3D printing technology, it solidifies immediately after printing and forms a 3D shape through multi-layer stacking. No need to wait for other processes such as shielding, vehicles, etc.

The axis controlled Axxon thermal conductive adhesive precision dispensing system adopts cutting-edge screw technology, demonstrating outstanding characteristics of low-pressure operation, no pulse discharge, and low shear strength. This design cleverly avoids the problem of adhesive delamination and evaporation caused by high-pressure environment, thereby effectively preventing the occurrence of adhesive curing phenomenon. At the same time, the system, with its ability to continuously supply glue without pulses, completely eliminates the phenomenon of backfilling and significantly reduces the cycle time (CT). In addition, the self sealing characteristic of the screw itself ensures the stability and accuracy of the dispensing precision, with an error controlled within ± 5%. This system also incorporates Axxon‘s unique switch valve design, supplemented by intelligent suction function, which not only effectively suppresses the phenomenon of dripping and trailing glue, but also significantly reduces the occurrence rate of problems with the size of the rubber strip. This system can integrate advanced 3D line scanning laser technology to achieve precise detection of core parameters such as adhesive strip length, width, height dimensions, area coverage, position accuracy, and adhesive defects. This function can efficiently intercept the flow of defective products into the assembly process, thereby achieving full closed-loop monitoring of dispensing detection while saving additional equipment costs and space resources.

DeSen Precision‘s high-precision fully automatic visual printing machine Classic 1009BTBL supports back-to-back operation and does not move the steel mesh when changing cleaning paper; Covering the printing process requirements for all circuit boards; Super strong alignment system, automatic compensation for printing angle, meeting 0201 and 01005 component requirements, applied in 5G, semiconductor Mini LED、 Automotive electronics, photovoltaic products, 3C, military aerospace, medical and other fields.

2026 Munich Shanghai Electronic Production Equipment Exhibition: Inviting You to Explore the Next Decade of Electronic Manufacturing Together

From micro level mounting to carbon neutral production lines, SMT technology is reshaping the industry boundary with three fold changes: miniaturization, intelligence, and greenness - miniaturization breaks the bottleneck of component integration, intelligence solves the problem of flexible production, and greenness responds to the global call for environmental protection. The 2026 Munich Shanghai Electronic Production Equipment Exhibition is not only a "testing ground" for technology landing, but also a "connector" for enterprises to connect with business opportunities and discuss the future. In addition to the above-mentioned enterprises, Shanghai Yishi Trading Co., Ltd. will also exhibit Panasonic‘s SMT machines and printing machines at the exhibition site. The exhibition will also bring together high-quality enterprises in the SMT industry, such as ASM, Kuaike, Ridong, Luyuan, Medtech, Indium Tech, Jiechuang, Huawang, Zhuhai Zhixin, Jintuo, Fujide, Jiali, Meiya Technology, Jiding Electromechanical, Huajida, Chenglian Kaida, Zhishengwei, Zhonghexu, Kaige Precision Machinery, and Shouwei. We cordially invite colleagues in the SMT industry to gather in Shanghai in March next year to join us in this innovative event and unlock new possibilities for electronic manufacturing!

The picture shows some participating companies in the SMT exhibition area of the 2026 Munich Shanghai Electronic Production Equipment Exhibition (ranked in no particular order)

Lock in your booth immediately and attend the electronic manufacturing event together

FUJI、Europlacer、Mycronic、Kurtz Ersa 、Rehm 、HELLER 、ITW EAE 、ASYS Group 、 Leading companies in the industry such as Guangdai, Borui Advanced, Yishi Trading, Ruitian Intelligence, Kuaike, Anda, Axis, and Desen will showcase their new products and solutions at the 2026 Munich Shanghai Electronic Production Equipment Exhibition! At present, there are only a few remaining booths. Please contact your exhibition sales representative or call Ms. Xing at 021-20205553 to seize the final spot. Showcasing innovative strength on the pinnacle stage of electronic manufacturing technology and exploring global business opportunities!

Disclaimer: There are risks in the market, so choose carefully! This article is for reference only and is not intended as a basis for buying or selling.