Análisis del margen bruto de la planta de procesamiento de parches smt: una encuesta en profundidad sobre la rentabilidad de la industria en 2025

Time:2025-11-24

Views:9

According to the financial report data of listed companies in 2024, the median gross profit margin of professional SMT outsourcing enterprises is 19.7%, including 22.3% for Shanghai Electric Power Co., Ltd. and 18.9% for Shenzhen Southern Circuit Co., Ltd. The difference lies in the fact that double-sided/multi-layer board mounting is 4-6 points higher than single panel mounting, and 01005 precision component mounting is 8-12 points higher than conventional 0805 components. The cost of raw materials accounts for approximately 55-65% (with PCB boards accounting for 30% and components accounting for 25%), and electricity costs account for approximately 1.2-1.8% of revenue in continuous production mode. Next, let‘s delve into the question of how much gross profit margin SMT surface mount processing plants have, and uncover the mystery of SMT surface mount processing plants‘ gross profit margins.

1、 What is the gross profit margin of SMT surface mount processing factory?

The gross profit margin of SMT surface mount processing plants is affected by various factors, usually fluctuating between 15% -30%, depending on the following key factors:

① Main influencing factors

1. Order size: The larger the batch size, the lower the allocation of fixed costs (such as equipment depreciation and setup time), and the gross profit margin may increase to 25% -30%; Small batch orders may only account for 15% -20%.

2. Technical complexity:

2.1 The gross profit margin of ordinary double-sided panel processing (such as consumer electronics) is relatively low (15% -20%);

2.2 High precision PCBs (such as automotive electronics and medical equipment) can reach 25% -35%, but require more expensive equipment and processes.

3. Customer type:

3.1 Long term cooperative clients may offer a discount of 18% -22% to maintain the relationship;

3.2 Small and medium-sized customers or temporary orders may account for over 25%.

4. Raw material procurement:

4.1 The gross profit margin of materials provided by customers (for processing with incoming materials) is relatively low (10% -15%);

4.2 Factory labor and material (including component procurement) can reach 20% -30%, but inventory risk must be borne.

② Cost structure (taking a typical factory as an example)

1. Remarks on the proportion of cost items (as a percentage of revenue).

2. The proportion of direct materials (components) in the 40% -60% labor and material packaging mode is high.

3. Labor costs are mainly based on 15% -25% of technical worker wages.

4. Equipment depreciation of 5% -10%. The depreciation cost of high-precision surface mount machines is high.

5. The rental pressure for water and electricity/factory buildings is significant in first tier cities, ranging from 5% to 8%.

6. Management/sales expenses of 5% -10% may result in higher customer development costs.

7. Theoretical gross profit margin calculation: If the revenue is 1 million yuan, the total cost is 700000 to 850000 yuan, and the gross profit is about 150000 to 300000 yuan (15% -30%).

③ Industry comparison

1. Low end processing plants: 15% -20% (relying on low price competition and outdated equipment).

2. Zhonggao Zhuo Factory: 20% -30% (capable of 0201 and below components, BGA packaging, etc.).

3. Experts in specific fields, such as military/aerospace SMT processing, can reach 35% -50%, but the threshold is extremely high.

④ The key to improving gross profit margin

1. Automation upgrade: reduce manual dependence (such as introducing AOI detection and intelligent warehousing).

2. Vertical integration: Expand PCB design, testing and other services to increase added value.

3. Supply chain optimization: Sign long-term agreements with component suppliers to reduce procurement costs.

⑤ Attention

The actual gross profit margin needs to deduct taxes, financial costs, etc., and the net profit margin is usually 5% -15%. Suggest conducting a specific analysis based on one‘s own capacity utilization rate (ideal value>80%) and customer structure. The gross profit margin of the new factory may be low in the first two years due to high equipment investment.

2、 Factors affecting the gross profit margin of SMT surface mount processing plants

① Raw material cost

The cost of raw materials accounts for a large proportion of SMT surface mount processing costs, including PCB boards, electronic components, solder paste, etc. Among them, the price of electronic components fluctuates frequently and is affected by various factors such as international market supply and demand, changes in raw material prices, and technological innovation. For example, the price fluctuations of certain rare metals may lead to a significant increase in the cost of related electronic components, thereby compressing the gross profit margin space of SMT surface mount processing plants.

In addition, the price of PCB boards may vary due to factors such as board material, thickness, and processing technology. Some high-precision and high-quality PCB boards are relatively expensive. If the processing plant does not have effective cost control measures in raw material procurement, it is easy to lead to high costs, which in turn affects the gross profit margin.

② Equipment and technology investment

SMT surface mount processing belongs to technology intensive and equipment intensive industries, and advanced equipment and technology are the key to ensuring product quality and production efficiency. A high-precision surface mount machine is expensive, and the maintenance, upgrading, and replacement of the equipment also require a large amount of capital investment. At the same time, in order to keep up with the pace of industry development, processing plants need to continuously invest in research and development resources, technological innovation, and process improvement to improve the added value and competitiveness of products. However, these equipment and technological investments will increase the fixed costs of enterprises. If the capacity utilization rate is insufficient or the product added value is not high, it is difficult to dilute these costs through large-scale production, which will have a negative impact on gross profit margin.

③ Labor cost

Although SMT surface mount processing has a high degree of automation, it still requires a certain amount of manual labor to complete processes such as material distribution, equipment operation monitoring, and quality inspection. But with the changes in the labor market, labor costs have been increasing year by year, especially in some economically developed areas where the wages of skilled workers remain high. In addition, in order to ensure product quality, processing plants also need to provide professional training for employees, which increases the expenditure on labor costs. If labor costs are not properly controlled, it will further compress profit margins and reduce gross profit margins.

④ Order size and production efficiency

The size of the order directly affects the production cost and gross profit margin of SMT surface mount processing plants. Large scale orders can achieve full utilization of equipment, improve production efficiency, reduce fixed costs per unit product, and thus increase gross profit margin to a certain extent. On the contrary, small orders may lead to prolonged idle time of equipment, low production efficiency, increased unit costs, and corresponding decrease in gross profit margin. In addition, production efficiency is also affected by factors such as production management level and process optimization degree. An efficient production management system can arrange production plans reasonably, optimize production processes, reduce waste and delays in the production process, thereby improving production efficiency, reducing costs, and increasing gross profit margins.

⑤ Market competition and product added value

In the fiercely competitive market environment, SMT surface mount processing plants often adopt a price reduction strategy in order to obtain orders, which directly leads to a decrease in gross profit margin. At the same time, if the products of the processing plants lack differentiated competitive advantages and rely solely on price wars to compete, it is difficult to obtain high profit margins. On the contrary, those processing plants that can provide high value-added products, such as SMT surface mount processing that focuses on high precision electronic products, high-precision industrial control equipment and other fields, due to their high product technology content and strict quality requirements, customers have relatively low sensitivity to prices, so they can obtain high gross profit margins. In addition, a good brand image and high-quality customer service can also increase the added value of products, improve customer loyalty, and help maintain high profitability. High gross profit margin level.

② Strategies to increase gross profit margin

1. Optimize supply chain management

2. Improve equipment utilization and technological level

3. Strengthen cost control and lean production

4. Expand high value-added business areas

5. Strengthen brand building and customer service

4、 The future development trend and gross profit margin outlook of SMT surface mount processing industry

5、 Regarding the SMT SMT SMT Processing Industry

6、 Baiqiancheng Company: Zhuoyue‘s Choice for Shenzhen SMT Processing

During the production process, Baiqiancheng Company strictly adheres to the ISO quality management system standards and has established a comprehensive quality control system. From the online inspection of PCB boards to the placement and soldering of components, to the testing and inspection of finished products, strict quality control is carried out at every stage to ensure that product quality meets international standards and customer requirements.

The company also implements the lean production concept, continuously improving production efficiency and product quality stability, reducing production costs, and providing customers with efficient and high-quality SMT surface mount processing services through measures such as optimizing process flow, improving equipment utilization, and reducing waste.

At present, Baiqiancheng Company has successfully provided high-quality SMT surface mount processing services to many well-known enterprises, involving multiple fields such as consumer electronics, automotive electronics, industrial control, medical equipment, etc. With its outstanding quality, efficient service, and good reputation, Baiqiancheng Company stands out in the fierce market competition and has won widespread praise and trust from customers.

If you are looking for a professional, reliable, and efficient Shenzhen surface mount processing manufacturer, Baiqiancheng Company will be your best choice. We will wholeheartedly provide you with high-quality SMT surface mount processing services to help your products succeed in the market.

The gross profit margin of SMT surface mount processing plants is influenced by various factors, including raw material costs, equipment and technology investment, labor costs, order size and production efficiency, market competition and product added value, etc. In the current fierce market competition environment, SMT surface mount processing factories need to start from optimizing supply chain management, improving equipment utilization and technological level, strengthening cost control and lean production, expanding high value-added business areas, and strengthening brand building and customer service in order to improve their gross profit margin, and continuously enhance their core competitiveness.

The article has comprehensively covered the content related to the gross profit margin of SMT surface mount processing plants. If you feel that certain parts require additional data, case studies, or adjustments to the presentation style, please feel free to let us know at any time.

3、 The current situation and improvement strategy of gross profit margin in SMT surface mount processing plants

① Current situation of gross profit margin

At present, the gross profit margin of SMT surface mount processing plants varies greatly, generally at a moderate to low level. Generally, the gross profit margin of SMT surface mount processing plants in the field of ordinary consumer electronics products is relatively low, around 10% -20%. This is because the consumer electronics market is fiercely competitive, with serious product homogenization and high price transparency. In order to compete for orders, processing plants often have to undertake business at lower prices, resulting in limited profit margins.

In some high-end fields such as automotive electronics, medical equipment, aerospace, etc., due to high product technology content, strict quality requirements, and high market entry barriers, the gross profit margin of SMT surface mount processing plants is relatively high, reaching 30% -40% or even higher. However, the market share of these high-end fields is relatively small, and the requirements for the technical strength, production capacity, quality management, and other aspects of processing plants are extremely high. Only a few enterprises with core competitiveness can enter.

② Strategies to increase gross profit margin

1. Optimize supply chain management

Strengthen cooperation with raw material suppliers, establish long-term stable supply relationships, strive for more favorable purchase prices through bulk procurement, signing long-term contracts, etc., reduce raw material costs, optimize inventory management, adopt advanced inventory management systems, monitor raw material inventory levels in real time, avoid excessive inventory backlog and capital occupation, improve capital turnover rate, actively expand raw material procurement channels, and find more cost-effective alternatives, which are also effective ways to reduce raw material costs.

2. Improve equipment utilization and technological level

Reasonably arrange production plans, fully utilize the production capacity of equipment, and improve equipment utilization. For idle equipment, it is possible to consider renting out or undertaking additional processing business to increase equipment revenue, while increasing investment in technology research and development, introducing advanced SMT surface mount processing technology and equipment, improving production process level, enhancing product quality and production efficiency. For example, using more automated surface mount machines, printing machines and other equipment can reduce manual intervention, improve production accuracy and stability, reduce defect rate, thereby reducing production costs and increasing gross profit margin.

3. Strengthen cost control and lean production

In the production process, the lean production concept is implemented to reduce production costs through measures such as optimizing process flow, reducing waste, and improving production efficiency. Strengthen the control of labor costs, arrange personnel positions reasonably, improve employee work efficiency, avoid personnel redundancy, and strictly control various expenses such as energy consumption and equipment maintenance costs to reduce the operating costs of the enterprise. In addition, establish a sound cost accounting system to accurately calculate and analyze the costs of each production link, timely identify weak links in cost control, and take targeted measures to improve them.

4. Expand high value-added business areas

Actively follow industry development trends, proactively layout high value-added markets, expand high value-added business areas, such as increasing research and development investment and market development efforts in high value-added fields such as automotive electronics, industrial control, medical equipment, etc., provide customers with one-stop SMT surface mount processing solutions, including product design, process optimization, testing and verification, and other value-added services to improve product added value and customer satisfaction. By establishing long-term and stable cooperative relationships with customers, gaining a deep understanding of their needs, continuously launching products and services that meet their personalized needs, and enhancing the core competitiveness and profitability of the enterprise.

5. Strengthen brand building and customer service

Pay attention to brand building, establish a good corporate image and brand reputation. By improving product quality, delivering on time, and providing high-quality after-sales service, we aim to win the trust and recognition of our customers, and enhance the brand‘s visibility and reputation.

In market competition, brand advantage can bring certain pricing power to enterprises, help improve product gross profit margins, strengthen customer service management, establish a sound customer service system, respond to customer needs and complaints in a timely manner, and enhance customer satisfaction and loyalty. Through high-quality customer service, not only can existing customer groups be consolidated, but more new customers can also be attracted, laying a solid foundation for the business development of the enterprise.

4、 The future development trend and gross profit margin outlook of SMT surface mount processing industry

In terms of intelligence, the widespread application of technologies such as artificial intelligence, big data, and the Internet of Things will promote the intelligent upgrading of SMT surface mount processing and production processes. By real-time collection, analysis, and processing of production data, intelligent monitoring, fault warning, production scheduling optimization, and other functions of equipment can be achieved, improving production efficiency and product quality, and reducing production costs. For example, by using machine vision technology to perform real-time detection of the surface mounting process, problems such as positional deviation and missing components can be detected in a timely manner and automatically adjusted, greatly improving the accuracy and reliability of production.

The degree of automation will be further deepened, and more automated equipment and robots will be applied to SMT surface mount processing production lines, achieving fully automated production from material distribution, surface mounting, welding to inspection and other aspects. This can not only improve production efficiency, reduce errors and quality issues caused by manual intervention, but also lower labor costs and enhance the competitiveness of the enterprise.

Fine production will become an important trend for future development. Especially with the development of electronic products towards miniaturization and high density, the precision and quality requirements for SMT surface mount processing are becoming increasingly high. Processing plants need to continuously improve their production process level, adopt more refined surface mount technology, higher precision equipment, and stricter quality control systems to meet the high quality requirements of customers for product quality. For example, in the installation of small components such as chip level packaging and microsensors, high precision and stability are required, which poses higher challenges to the technical strength and equipment accuracy of SMT surface mount processing enterprises.

The concept of green environmental protection will run through the entire SMT surface mount processing industry: with the increasingly strict environmental regulations and the society‘s emphasis on environmental protection, processing plants need to reduce the use of harmful substances in the production process, reduce energy consumption, strengthen the treatment and recycling of waste, such as promoting the use of lead-free solder, environmentally friendly cleaning agents and other green materials, adopting energy-saving equipment and processes, and achieving clean production. This not only helps protect the environment, but also enhances the social image and brand value of enterprises.

Analysis of gross profit margin of SMT surface mount processing factory

5、 Regarding the SMT SMT SMT Processing Industry

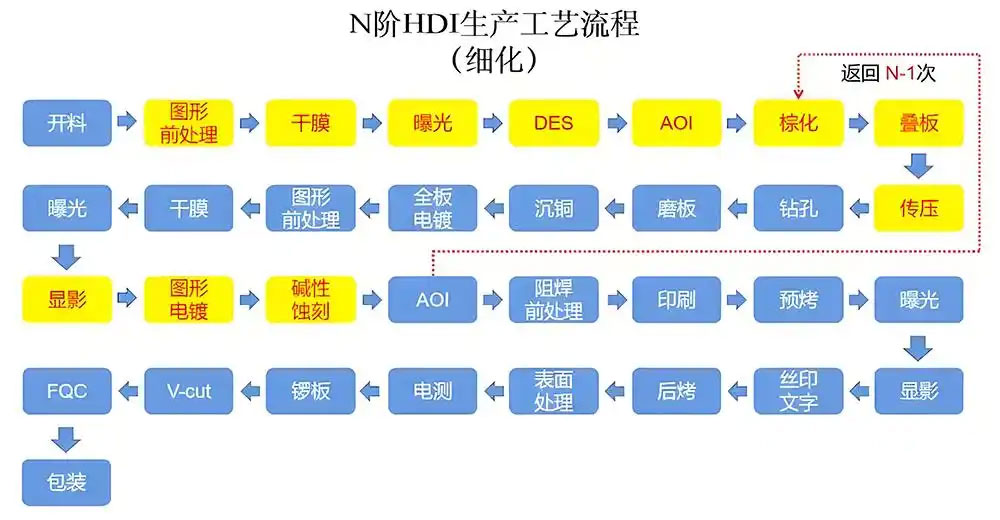

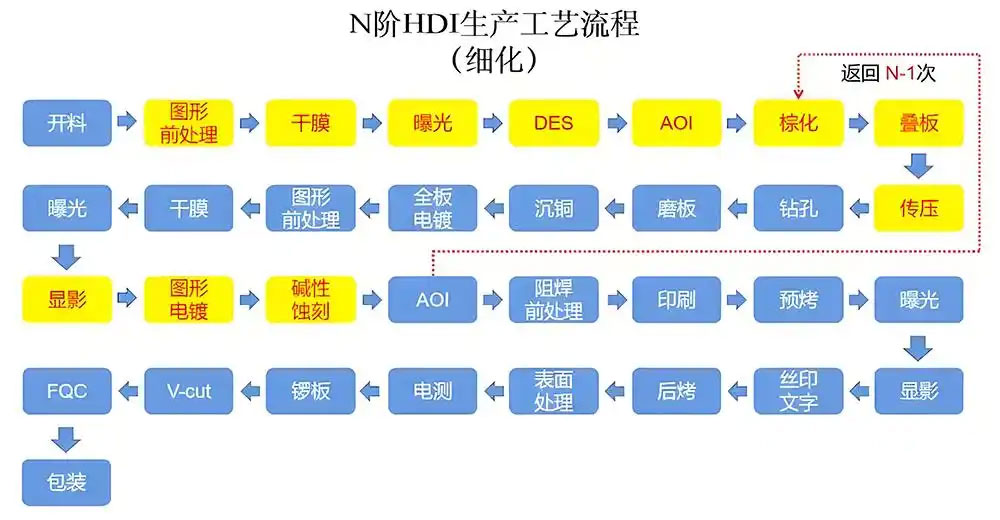

① The process flow of SMT surface mount processing

The process flow of SMT surface mount processing is complex and delicate, like a precise industrial dance. The basic process includes solder paste printing, part mounting, reflow soldering, AOI optical inspection, maintenance, and board splitting.

The solder paste printing process is like setting up a stage for electronic components, using a screen printing machine to accurately leak solder paste onto the solder pads of the PCB. This process requires extremely high precision from printing equipment, and even small differences in parameters such as scraper pressure and printing speed can affect the printing quality of solder paste.

Part mounting is like a dancer in place. The high-speed surface mount machine, with the help of advanced visual alignment system, can accurately install tiny components into the fixed position of the PCB in a very short time, with a mounting accuracy of ± 25 μ m or even higher.

Reflow soldering is a key step in achieving a tight embrace between components and PCBs. Through specific temperature curve control, the solder paste melts, forming a strong metal alloy connection between the component pins and PCB pads.

AOI optical inspection is like a rigorous judge, using high-precision optical lenses to comprehensively inspect the soldered PCB board, promptly detecting issues such as component offset, polarity errors, missing parts, etc., to ensure product quality.

If a problem is detected, it will enter the repair process. Experienced technicians will use tools such as soldering irons and repair workstations to carefully repair the faulty PCB board, and then divide the large PCB board into small pieces that meet product requirements through board splitting.

② The Position and Role of SMT Surface Mount Processing in the Electronic Manufacturing Industry

In the vast system of the electronic manufacturing industry, SMT surface mount processing occupies a core position and can be regarded as the heart of electronic product manufacturing. It is the key technical support for achieving miniaturization, lightweighting, and high performance of electronic products.

Electronic products now not only pursue smaller sizes and lighter weights, but also expect to have more powerful functions and higher reliability. SMT surface mount processing technology precisely meets these needs by densely assembling a large number of tiny components on PCB boards, greatly improving the integration of electronic products while reducing their weight and volume.

Today‘s smartwatches integrate numerous functions into their compact dials, such as heart rate monitoring, motion tracking, communication, etc. This is inseparable from the efficient assembly of various precision components using SMT surface mount processing technology. The high precision and reliability of SMT surface mount processing technology also effectively improve the quality and stability of electronic products, reduce the probability of failures caused by component connection problems, and inject strong impetus into the vigorous development of the electronic manufacturing industry.

Compared with traditional plug-in component assembly methods, SMT surface mount processing has many significant advantages such as high component density, small size, light weight, and high reliability, which can effectively meet the pursuit of high performance and miniaturization in modern electronic products.

In recent years, the SMT surface mount processing industry has also ushered in a golden period of rapid development. From consumer electronics products such as smartphones and tablets to high-end fields such as automotive electronics, industrial control, and medical equipment, the application scope of SMT surface mount processing continues to expand, and market demand continues to grow. According to relevant industry reports, the global SMT surface mount processing market has shown a steady upward trend in the past few years, and is expected to maintain a high growth rate in the coming years. This undoubtedly provides broad development space for SMT surface mount processing factories.

But with the rapid expansion of the market, industry competition is becoming increasingly fierce. More and more companies are entering this field, making the competition for market share increasingly fierce. In the fiercely competitive environment, in order for SMT surface mount processing plants to stand out, they not only need to rely on advanced technology and equipment, efficient production management, but also need to closely monitor their own profitability, especially gross profit margin level, to ensure that the enterprise has sufficient competitiveness and sustainable development capabilities in the market.

6、 Baiqiancheng Company: Zhuoyue‘s Choice for Shenzhen SMT Processing

In Shenzhen, a vibrant and innovative hub for the electronics industry, Baiqiancheng Company has emerged in the field of SMT surface mount processing with its years of industry experience, advanced technology and equipment, professional team, and high-quality services, becoming a trusted partner for many customers.

Baiqiancheng Company has a highly qualified and experienced technical team, whose members possess profound professional knowledge and rich practical experience, and can proficiently master various advanced SMT surface mount processing technologies and processes. The company has introduced a series of internationally leading SMT surface mount processing equipment, such as high-precision surface mount machines, multifunctional printing machines, automated reflow soldering furnaces, etc. These equipment have the characteristics of high speed, high precision, and high stability, which can meet the requirements of different customers for product quality and production efficiency.

In terms of raw material procurement, Baiqiancheng Company has established long-term and stable cooperative relationships with numerous well-known suppliers. Through strict supplier screening and quality management systems, the company ensures the reliable quality and reasonable prices of the purchased raw materials. At the same time, the company focuses on cost control and supply chain optimization, reducing raw material procurement costs and inventory costs through refined management methods, and providing customers with more cost-effective products and services.

During the production process, Baiqiancheng Company strictly adheres to the ISO quality management system standards and has established a comprehensive quality control system. From the online inspection of PCB boards to the placement and soldering of components, to the testing and inspection of finished products, strict quality control is carried out at every stage to ensure that product quality meets international standards and customer requirements.

The company also implements the lean production concept, continuously improving production efficiency and product quality stability, reducing production costs, and providing customers with efficient and high-quality SMT surface mount processing services through measures such as optimizing process flow, improving equipment utilization, and reducing waste.

In addition to high-quality products and efficient production services, Baiqiancheng Company also focuses on customer service experience. The company has established a dedicated customer service team that can respond to customer needs and inquiries in a timely manner, providing customers with comprehensive technical support and solutions. Whether in the product development stage or in the mass production process, Baiqiancheng Company is able to work closely with customers, provide customized services according to their needs, and help customers solve various technical and production problems.

At present, Baiqiancheng Company has successfully provided high-quality SMT surface mount processing services to many well-known enterprises, involving multiple fields such as consumer electronics, automotive electronics, industrial control, medical equipment, etc. With its outstanding quality, efficient service, and good reputation, Baiqiancheng Company stands out in the fierce market competition and has won widespread praise and trust from customers.

If you are looking for a professional, reliable, and efficient Shenzhen surface mount processing manufacturer, Baiqiancheng Company will be your best choice. We will wholeheartedly provide you with high-quality SMT surface mount processing services to help your products succeed in the market.

The gross profit margin of SMT surface mount processing plants is influenced by various factors, including raw material costs, equipment and technology investment, labor costs, order size and production efficiency, market competition and product added value, etc. In the current fierce market competition environment, SMT surface mount processing factories need to start from optimizing supply chain management, improving equipment utilization and technological level, strengthening cost control and lean production, expanding high value-added business areas, and strengthening brand building and customer service in order to improve their gross profit margin, and continuously enhance their core competitiveness.

The article has comprehensively covered the content related to the gross profit margin of SMT surface mount processing plants. If you feel that certain parts require additional data, case studies, or adjustments to the presentation style, please feel free to let us know at any time.