PCBA processing:Why can‘t manual soldering be replaced by SMT patches?

Time:2025-08-30

Views:116

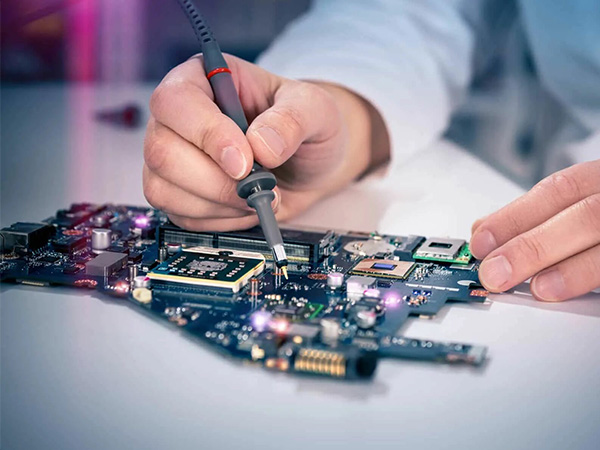

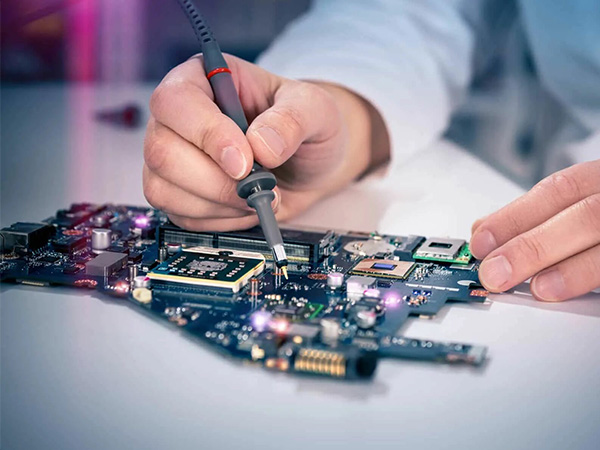

At a time when SMT chips dominate PCBA automated production, manual soldering is still the key to ensuring yield and meeting complex needs, and its core stems from its four irreplaceable values:

1. Technical advantages that break through the limitations of SMT

1.Micro component accuracy control: For LQFP, CSP and other devices with a pitch of less than 0.2mm, a 30W constant temperature soldering iron (310-330°C) + 0.12mm solder wire for manual soldering is used to avoid false soldering with "touch" operation (0.6-1.0 seconds / solder joint), and the pass rate in the aerospace field exceeds 99.8% after double testing.

2.Small batch cost reduction and efficiency improvement: Orders below 500pcs do not require SMT equipment debugging and stencil production, and production can be started within 24 hours, reducing costs by 40%-50%, adapting to R&D and proofing needs.

3.Precise rework: BGA chip rework uses a heat gun to control the temperature in stages, and with a solder suction tape to clean the pads, the yield rate is 99.6%, avoiding damage to components by heating the whole board.

4.Special substrate adaptation: When soldering FPC and ceramic substrates, it is supported by low-temperature soldering (138°C) and silicone pad or pressure control (<=50g) to prevent cracking and deformation.

2. Core application scenarios

Mixed processes (medical/industrial equipment with coexistence of SMT+THT components), high-end customization (military radiation-resistant chip welding), R&D proofing (quick replacement component debugging), old equipment maintenance (replacement of discontinued components) and special processes (low-loss welding of coaxial cables) all require manual welding support.

3. Practical operation and collaborative trend

Technicians need to hold IPC-A-610E certification, environmental temperature control of 20-25°C, humidity 40%-60%, and daily calibration of tools. In the future, manual soldering will be synergized with SMT: large-scale orders rely on SMT for production, and manual welding and repair; Small batch orders are all manual, with machine vision to improve accuracy.

Manual soldering is not a traditional residue, but the core competitiveness of PCBA production, and enterprises need to build standardized processes and maintain professional teams to adapt to diverse needs.