Medical PCBA OEM Screening Guide: The Golden Triangle of Technology, Quality, and Service - Chengdu Dali Electronics

Time:2025-09-01

Views:109

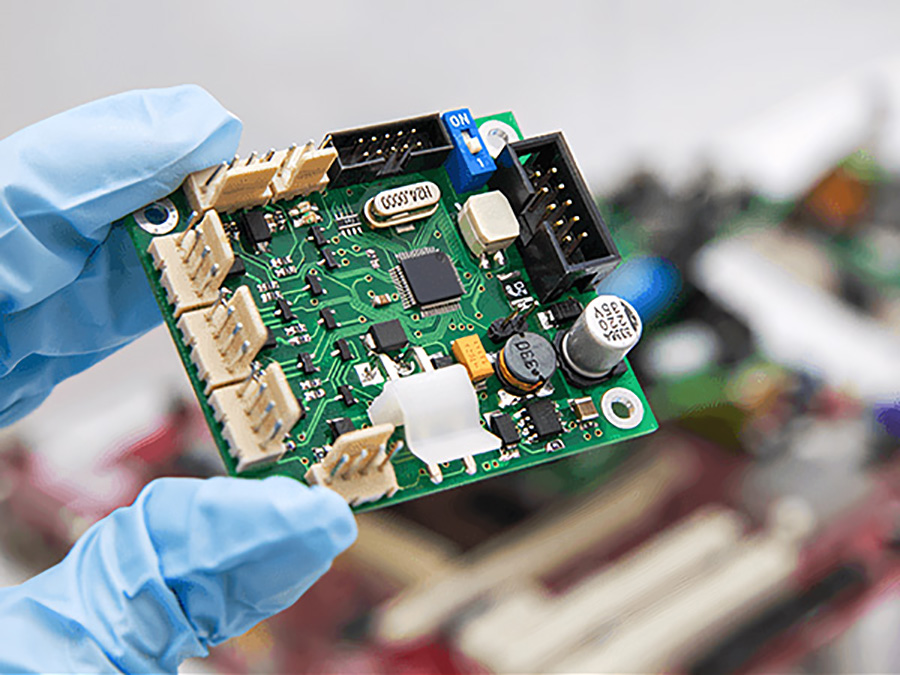

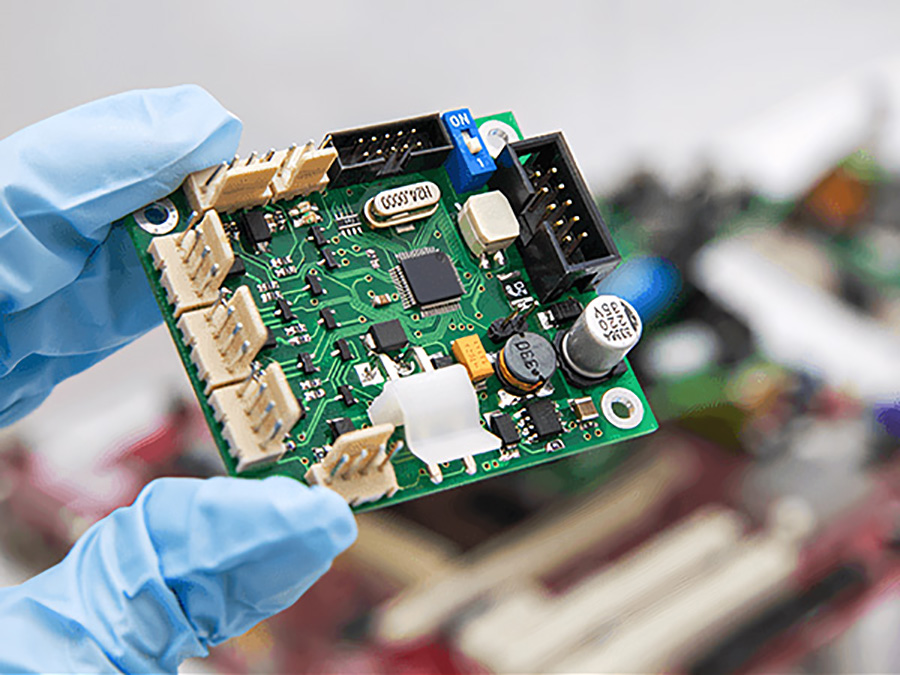

The quality of PCBA in medical equipment is directly related to the safety of patients‘ lives, and its OEM selection needs to be more stringent than that of consumer electronics. This article provides a practical screening framework from four dimensions: technical threshold, quality bottom line, industry experience, and service flexibility, to help medical enterprises avoid supply chain risks.

Basic threshold (mandatory)

Advanced abilities (bonus points)

Strategic value (long-term cooperation)

Decision tool: Quick screening checklist

Conclusion: From Suppliers to Strategic Partners

Basic threshold (mandatory)

1. Technical Capability: Hard Standards for Medical PCBA

• Core equipment requirements

✓ 0.3mm pitch BGA placement machine (for micro components)

✓ Multi zone reflow soldering (precise temperature control to avoid thermal damage)

✓ Full inspection equipment: AOI+SPI+X-RAY (defect rate ≤ 0.1%)

• Complex process validation

✓ Ability to process blind buried holes and optimize high-frequency signals

✓ BGA/QFN packaging mass production case (test report required)

2. Quality System: The Lifeline of the Medical Industry

• Certification qualifications

✓ ISO 13485 (for medical devices)+ISO 9001 dual certification

• Full process control

✓ Lead free and halogen-free material traceability system

✓ SPC real-time monitoring (yield fluctuation warning)

✓ 100% aging testing and environmental stress screening of finished products

Advanced abilities (bonus points)

1. Industry experience: Hidden competitiveness

Priority of successful cases

✓ Cases of monitors, MRI/CT equipment, wearable medical devices

✓ FDA/CE certification support (EMC testing pre qualification capability)

Supply chain resilience

✓ Sign direct agreements with original manufacturers (TI, ST, etc.) to address the risk of stock shortages

2. Service Resilience: Balancing Efficiency and Cost

• Flexible production mode

✓ Support small batches and multiple batches (such as 500 sets+1000 sets mixed orders)

DFM optimization service

✓ Reduce production cycle by 30% through layout optimization

Strategic value (long-term cooperation)

1. Future compatibility

• Technological foresight

✓ AI chip integration capability (supporting edge computing PCBA)

✓ Green manufacturing (RoHS/REACH compliance)

Digital management

✓ MES system achieves production data transparency

Decision tool: Quick screening checklist

Do you provide batch testing reports for MRI equipment PCBA?

Can we respond to quality issues within 24 hours?

Does the quotation include the cost of EMC certification assistance?

Conclusion: From Suppliers to Strategic Partners

The choice of medical PCBA outsourcing needs to go beyond the "outsourcing" mindset, prioritizing the factory‘s medical industry focus (case authenticity), strict quality system (defect rate improvement mechanism), and supply chain risk resistance (original factory cooperation depth). Suggest gradually establishing long-term cooperation through trial production verification (≤ 500 sets).

Chengdu Dali Electronics Co., Ltd. is a national high-tech enterprise that integrates high-end FPGA/MCU solution design and professional PCBA surface mount manufacturing. We specialize in providing full stack solutions for industrial automation, consumer electronics, medical equipment, and other fields, from core hardware design and software development to high-quality manufacturing. We are particularly skilled in innovation and application of industrial grade audio and video processing technology.

Chengdu Dali Electronics Co., Ltd. is a national high-tech enterprise that integrates high-end FPGA/MCU solution design and professional PCBA surface mount manufacturing. We specialize in providing full stack solutions for industrial automation, consumer electronics, medical equipment, and other fields, from core hardware design and software development to high-quality manufacturing. We are particularly skilled in innovation and application of industrial grade audio and video processing technology.